Lathing

From the rough to the detail

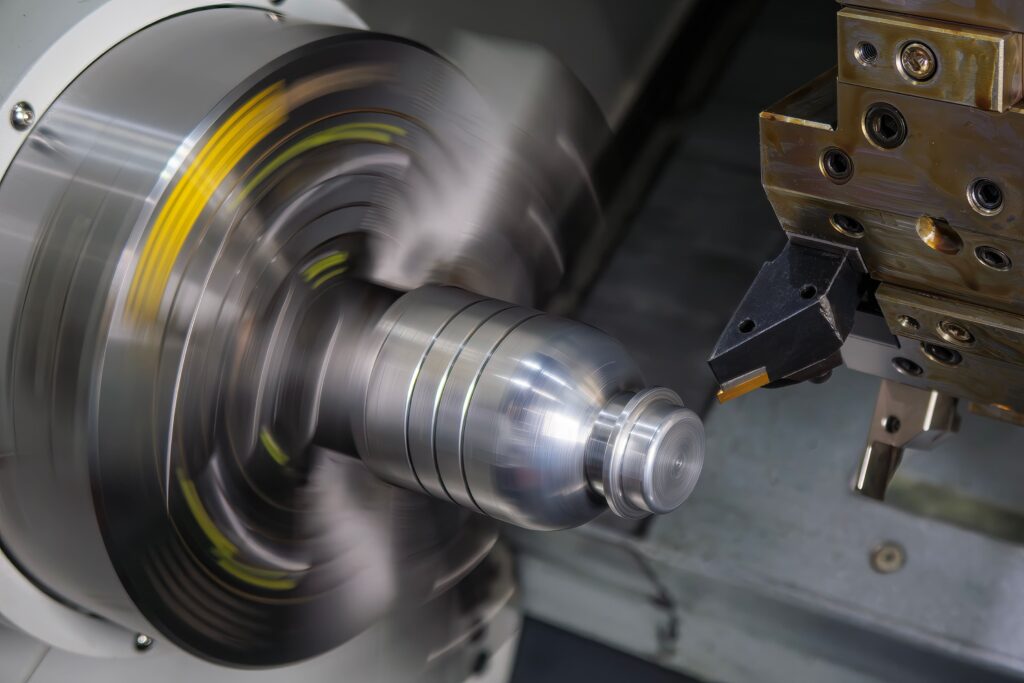

Turning is a widely used and efficient metalworking process where a rotating workpiece or blank is machined with a cutting tool to achieve the desired shape and dimensions. This method is ideal for the manufacture of cylindrical, tapered and threaded parts, including shafts, bushes and pins.

Our state-of-the-art range of CNC lathes allows for high precision and uniform surface finishes, while offering the flexibility to produce both small batches and high volume serial production. Thanks to our multi-axis lathes, we can also produce complex geometries and ensure repeatability in every production run.

Materials for turning

Our turning services cover a wide range of materials, offering flexibility and suitability to the needs of different industries. We process a wide range of metallic materials, including steel, stainless steel, aluminium, vasc, and various alloys, which are well suited for the production of various mechanical and structural components. In addition to metalworking, we are also able to turn other materials such as. plastic and composites, which are often needed for specific applications.

Our state-of-the-art CNC lathes allow for high precision cutting and finishing of the materials to be machined, while maintaining the quality and durability of each part. Whether it's heavy steel parts or lighter aluminium parts, we always ensure high levels of machining and precision.

The choice of material is important, both in terms of mechanical properties and processing method, so we always help our customers to select the best material to meet the specific requirements and objectives of their project.

Precision machining and complex parts

The features of our CNC lathes allow precision turning of the most complex parts. Precision turning means working with high accuracy and small tolerances, which is particularly important in mechanical systems where every millimetre or micrometre counts. Thanks to our multi-axis machine tools, we can produce parts with complex geometries, including complex threaded parts, hollow shafts and special mechanisms.

The production of complex parts requires not only precision, but also the ability to adapt the process to the requirements of the project. Our equipment and experienced team ensure that each part is manufactured to the customer's specification and precision requirements. Regardless of the complexity of the project, we are able to produce high quality parts for both low and high volume production, ensuring consistent accuracy in every production run.

Larger and smaller production series

Our turning services are flexible, allowing you to work with both small and large production runs. Whether you need a single prototype or thousands of parts for mass production, we can adapt our processes to the size and schedule of your project.

For small batches, we focus on the precision and quality of each piece, ensuring that even the smallest orders meet the highest standards. At the same time, during the prototyping phase, we also create a plan to produce the same parts in large quantities, efficiently and with high quality.

For larger production runs, our CNC technology ensures consistency and production efficiency. Thanks to our automatic material loading systems and precision turning machines, large batches can be produced quickly and accurately, maintaining consistent quality in every part. We also optimise the process at every stage of production to keep costs under control and constantly look for ways to increase efficiency.

Turning services in combination with other metalwork

Our turning services are just one part of our wider portfolio of metalwork services. We offer the possibility to combine turning with other metalworking services, such as. welding, Sawing and CNC millingto achieve complete production solutions. This integrated approach allows us to manage complex projects where the integration of different processes is required, ensuring consistent quality and production efficiency.

For example, if your project requires welded parts with precision-machined components, or the machining and assembly of dissimilar metals, we can provide. comprehensive solutions, covering all stages from start to finish. This multi-faceted approach reduces supply chain complexity and ensures that all processes are carried out under one roof, saving resources for all.